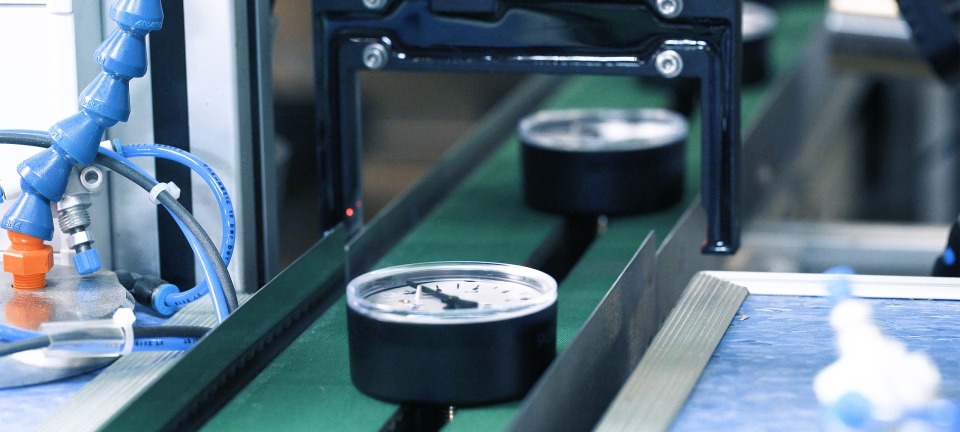

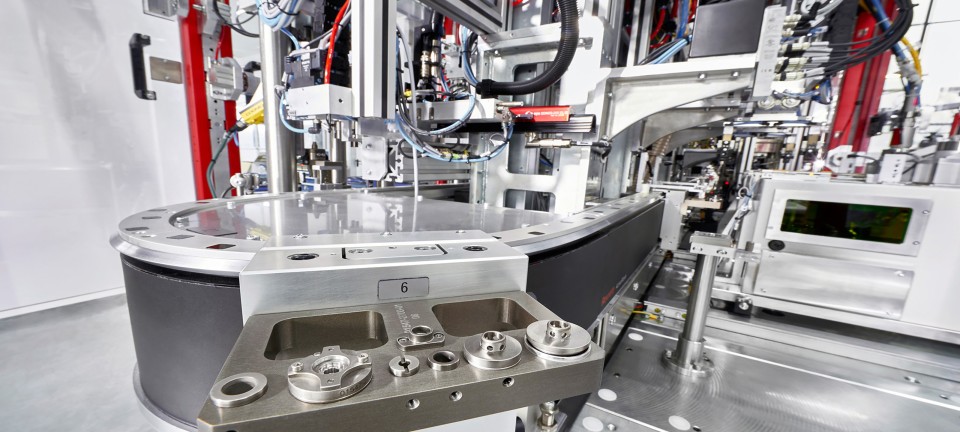

High speed, rapid acceleration and a low-friction, magnetic clutch help reduce cycle time. Workspiece pallets can be moved indepently to any defined position, even along curves, at a wide range of acceleration rates and speeds smoothly and with precision. All this while also remaining easily accessible, giving you maximum accessibility to the workpiece.

Reducing your product's cycle time: that moves us.